Of course, there are multiple different ways of even sketching the basic wall corner section footprint.

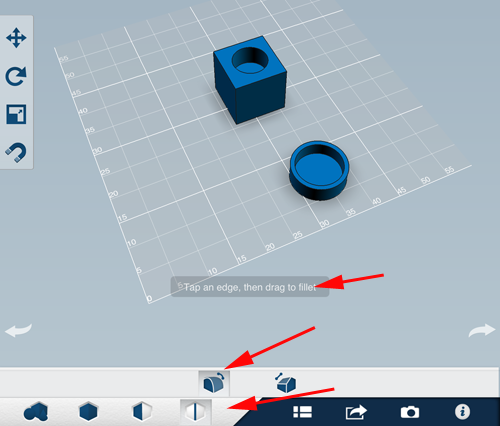

The reason for the difference of 5 units between the inside and outside surfaces’ respective corner curvature radii is to account for the thickness of the wall itself, which we chose to be 5 units in this particular example and which constitutes the distance between the inside and outside surfaces of the wall and is thus necessarily also the difference between the inside and outside curvature radii of the swept corner. With the first approach, we initially sketch and extrude the wall section as a straight, 90° corner but then use the Fillet tool on both the inside and outside corner seams to introduce a curvature with a radius of 10 units to the inside surface of the wall and one with a curvature of 15 units to its outside surface.

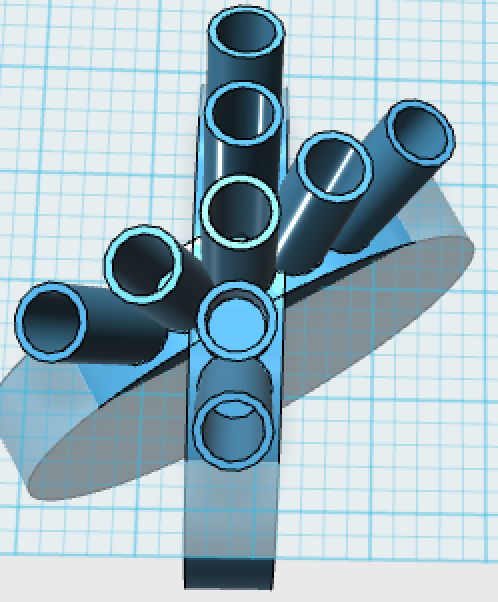

The following is a short video showing several different ways to model the same basic shape: two straight walls at a 90° angle from one another joined through a curved corner. For instance, the only way one can go about producing truly accurate spirals or threading (as on a bolt or nut) inside of 123D Design really only is by using the Loft operation with a high enough number of profiles as guides. When there really is only one way to achieve exactly the desired outcome, you can generally expect to have to rely on some of the more exotic tools in the 123D Design tool set, such as the Loft or Sweep operations. For example, such is the case if one wants to accurately model a spiral or threading in 123D Design, which can only be done accurately using the Loft tool. Sometimes, the best and most accurate results require the most elbow grease and time and can be the most tedious to achieve. Also, the different ways you can go about modelling the same thing may pose varying degrees of difficulty or involve different numbers of steps and each require a different amount of work and time input. These different approaches may yield exactly identical results or the results they produce may differ to a greater or lesser degree and not all of them might end up doing exactly what we had planned or intended to achieve. Today we’re going to talk about how there is often (though certainly not always) more than one way to achieve the same or roughly the same basic shape or design using the tools available in 123D Design and how there are often several different approaches to the same task.

0 kommentar(er)

0 kommentar(er)